Along the Greene River Trail

Crucible Mine

1911-1944

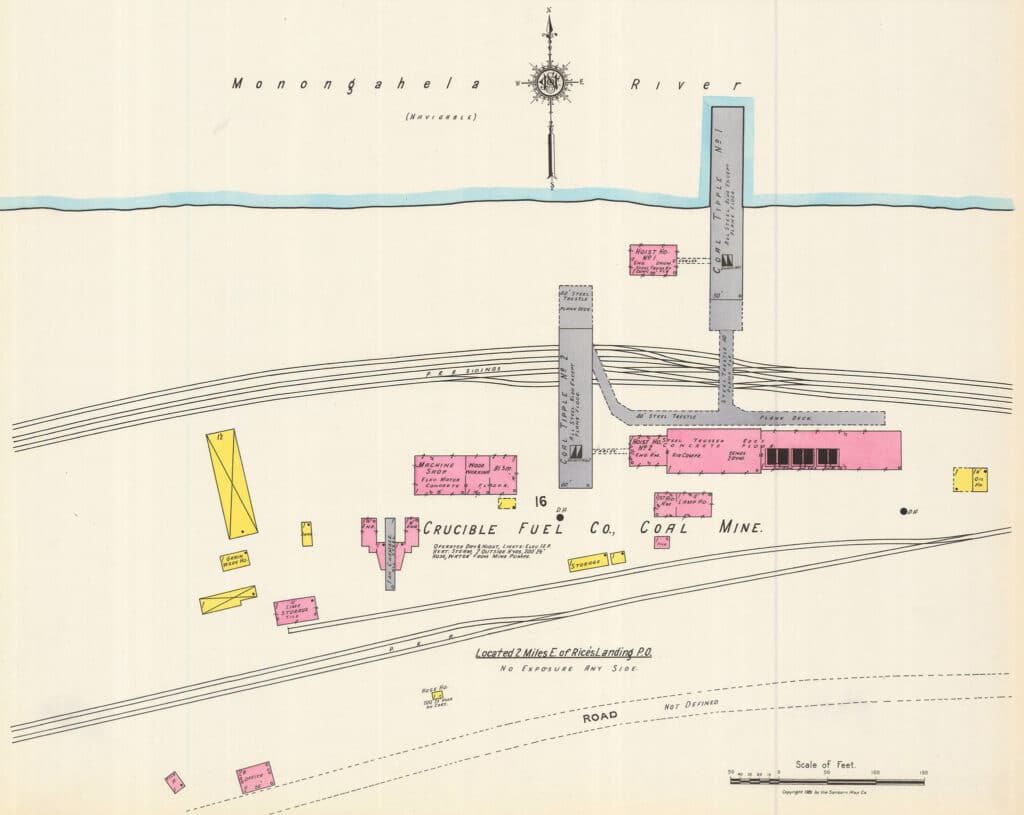

In 1911, the Crucible Coal Company began to develop Greene County’s second largest mine. Located along the Monongahela River, less than two miles south of Rices Landing, the high quality coal from the Pittsburgh seam was to be shipped to Midland to be converted to coke for the company’s new steel mill. Approximately 2,000 acres were purchased from J.V. Thompson and associates in February of 1911.

In the spring, Crucible Coal announced plans to construct two shafts, an air shaft, large tipple, 150 steel barges and 100 miner houses. They also bought the surface acres of three farms, the Arensburg ferry and a new steam ferry. They used the ferry to transport materials for construction from the Fayette County side of the river. Construction of the shafts, tipple and a new road up the hill, where the mining town was to be built, began in August. By November the number two shaft was complete and the first coal was taken from the mine. By 1913, 166 men were employed by the mine and they had removed 120,126 tons of coal.

The late 1920s saw the highest production values. Crucible produced about one million tons of coal in each of those years and averaged employment of over 800 miners. During the Depression, mining was hit hard and production at Crucible was down to 368,000 tons and 336 miners were employed in 1932. The mine remained open while other mines closed, but at times they were only operating a few days a week. The nationwide “Share the Work” movement was encouraging companies to share full time jobs amongst several employees to reduce unemployment and relief expenditures. The coal mines were using job sharing, but with lower demand for coal, there wasn’t that much work to be done.

1945-1984

The onset of World War II brought increased demand for coal and this continued into the building boom that followed the war. Greene County had 45 deep mines, 8 strip mines, employed 9,910 miners and produced over 12 million tons of coal. Crucible produced over one million tons and employed over 800 miners. This level of production remained that same for the next twenty years, however mechanization caused a steady decline in employment.

The Crucible Mine suffered a sharp drop in production after 1957 and production stopped in October 1961. The mine was no longer competitive in producing the quality of coking coal needed for the steel company’s specialty steels. From 1913 to 1961, Crucible Mine produced over 36.5 million tons of coal from the Pittsburgh seam.

After the Crucible Coal Company closed the mine, it was maintained by Pittsburgh Coal Company and then conveyed to National Mines Corporation. A tunnel was dug under the Monongahela River to connect with the Isabella Mine, owned by Weirton Steel of Wheeling, in Fayette County. Coal continued to be removed from Crucible reserves until the Isabella Mine closed in 1984.

Mine Mules

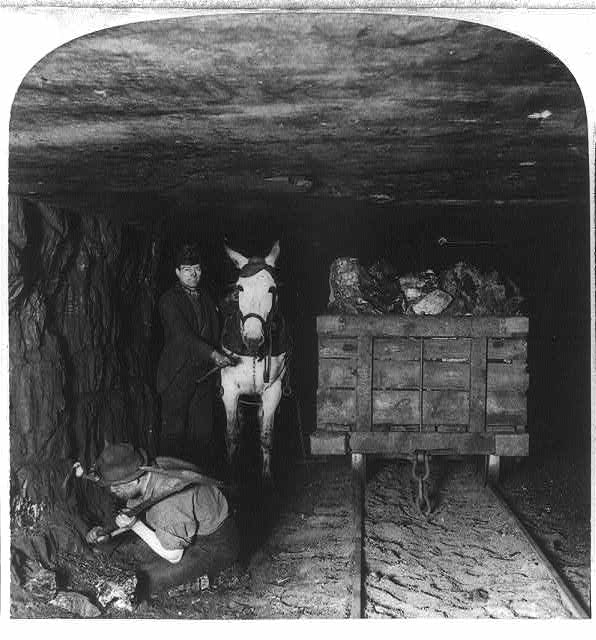

Mining the coal is one kind of challenge, while bringing it out of the deep mines is a different challenge. Prior to World War II, it was loaded into coal cars on tracks and brought to the surface. Many different methods were used to bring the cars out of the mines and one of those is the mine mule.

The mule is the offspring of a male donkey and a female horse. An exceptional beast of burden, it has the small sure feet and endurance of the donkey with the larger body, strength and temperament of a horse. Mules resist disease well and are able to do the work of a horse under harsh conditions. In 1913, mules cost about $200. They could begin work at the age of 3 and lived to 30.

To save on transportation time, the mules were often stabled in the mines. The stables were much like above the ground stables. The mules had feed and straw, they were housed in stalls, and equipment was hung on the walls. The mules rarely saw the outside world. They developed night vision like owls and other nocturnal animals. Usually they were only taken outside if they needed to see the blacksmith, veterinarian or when the mine was shut down for various reasons. The mules were highly valued and often some of the miners would visit with them on their lunch breaks or when arriving or leaving for work.

Eventually, the use of electric locomotives, mechanization and conveyors began to gradually replace mules. The animal welfare and safety regulations of the 1960s and 70s ended the use of mules in any mine in the United States.

About the Greene River Trail Signage Project

Greene County Tourist Promotion Agency completed this project in partnership with the Rivers of Steel Heritage Area. Funding was provided in part by a grant from the Pennsylvania Department of Conservation and Natural Resources, Bureau of Recreation and Conservation, administered by Rivers of Steel.

Special thanks to: Brice & Linda Rush, Danielle Nyland, Flenniken Public Library, Greene County Historical Society, Greene Connections, Advanced Masonry, Greene County Commissioners, Greene County Conservation District, and Greene County Department of Recreation.